1. Background

A residential retirement village in South-East Queensland contained several caravan homes installed on concrete and timber block supports. Due to minor settlement in the ground, periodic flooding and insufficient stormwater drainage, the village management initiated a lifting and re-levelling program to restore the caravans to a safe level position.

Budget constraints led management to use an unlicensed contractor who performed the lifting without following the requirements of the Australian Standards and manufacturer’s guidelines. The lack of compliant methodology resulted in widespread structural issues across all caravan homes.

This case study examines one representative caravan (Unit 14) to illustrate how non-compliant lifting practices affected structural integrity.

2. Description of Caravan Unit 14

- Type: Lightweight relocatable dwelling

- Age: 11 years

- Foundation configuration:

- Multiple stacked concrete blocks and timber packers

- No tied-down anchorage system

- Weight distributed on 14 primary support points

- Framing: Light-gauge steel chassis with timber-framed floor and walls

- Condition prior to lifting: Minor settlement (an average of approximately 20mm) with no major structural defects

3. Non-Compliant Lifting Approach Used

The contractor employed the following practices, all contrary to industry standards:

3.1 Single-point hydraulic jacking

Only one jack was used at a time, causing:

- Uneven load transfer

- Twisting of the steel chassis

- Sudden point-load spikes

- Racking forces on walls and roof

3.2 Unsupported block stacks

Blocks were:

- Irregularly stacked

- Sometimes placed on soft soil

- Not aligned vertically

- Not interlocked or restrained

3.3 No monitoring of structural movement

There was:

- No use of laser level or string-line

- No monitoring of frame behaviour during lift

- No staged lift plan at nominated increments

3.4 Lifting beyond manufacturer limits

The caravan was lifted more than 90 mm in a single session, exceeding the recommended maximum incremental lift per cycle.

4. Observed Structural Impacts

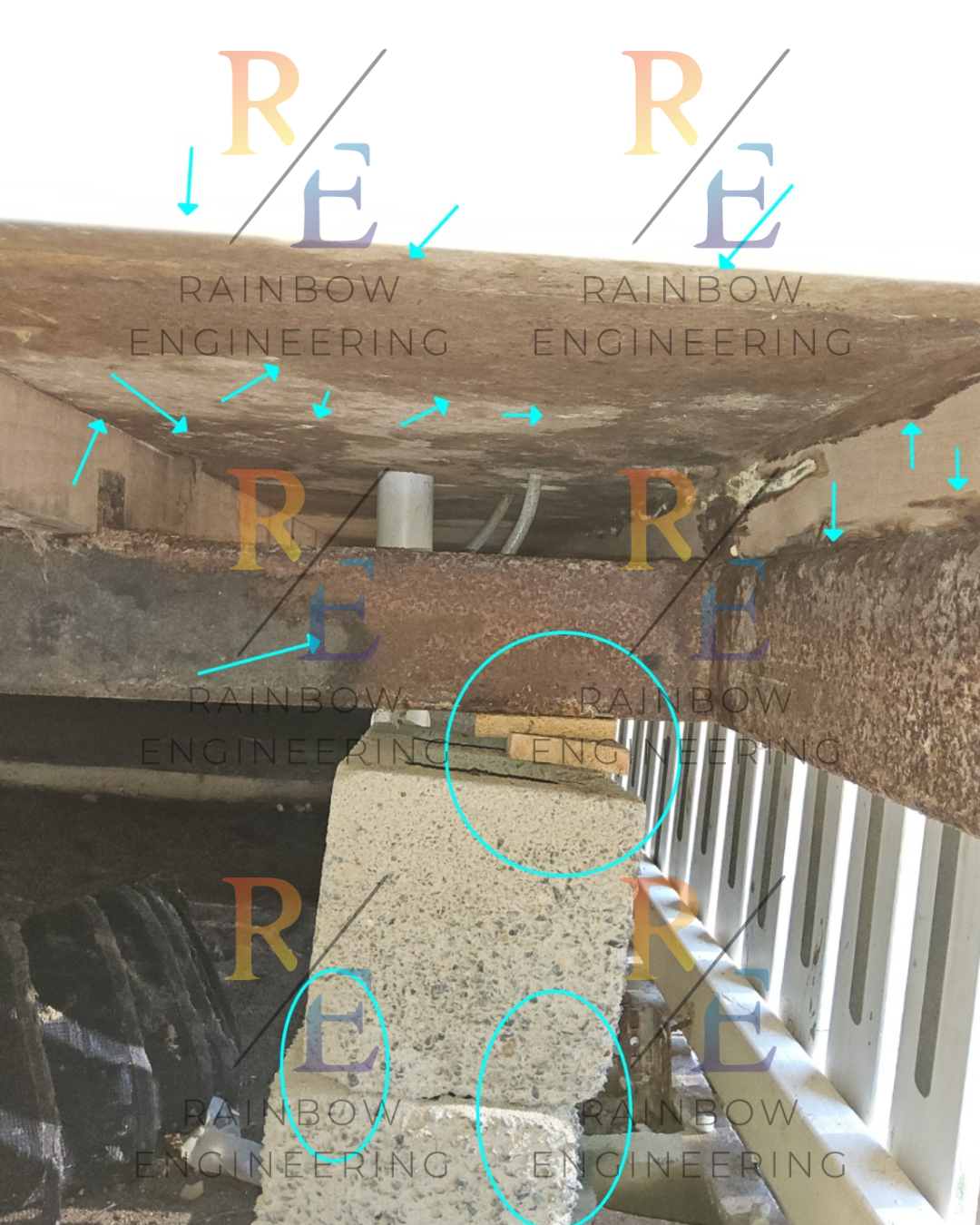

4.1 Chassis Distortion

- Residual twist of 18 mm measured diagonally across the steel chassis

- Welded joints near axle mounting plates showed stress cracking

- The frame became misaligned by upto 8 mm

Cause: the uneven jacking created torsional loads that the chassis was not designed to resist.

4.2 Floor Deformation

- Floor sheets cracking developed near the kitchen area

- Floor sheeting began separating from joists

- Several joists experienced uplift on one side and crushing on the other

- Bathroom no longer functions due to breakage in plumbing pipes

Cause: Block misalignment forced partial load into the centre of the caravan rather than being distributed evenly across peripheral supports.

4.3 Wall Racking and Plasterboard Cracking

- Internal plasterboard cracking at wall-ceiling junctions

- External cladding showed diagonal buckling near window corners

- Door frames became skewed, preventing proper closure

Cause: Frame racking due to rapid, uneven lifting.

4.4 Roof Structure Stress

- Water pooling observed after rain due to altered roof pitch

- Flashings pulled away from junctions

Cause: Distortion transferred upward through the wall studs and trusses.

4.5 Service Damage

The following service defects were noted after the lift:

- Wastewater pipe pulled out of alignment causing leaks

- Electrical conduit stretched and cracked

- Water supply line under the chassis kinked and later ruptured

Cause: No isolation or service disconnection before lifting.

5. Safety and Compliance Issues Identified

The lifting works breached several key requirements:

Non-compliance with:

- AS 1684 – Residential timber framing

- AS 1170.1 – Structural actions (loadings)

- AS 3000 – Electrical safety

- Manufacturer’s installation manuals

- Local council regulations for relocatable dwellings

Key safety risks:

- Collapse of block stacks

- Chassis fatigue and sudden failure

- Fire or electrical hazards due to cable damage

- Reduced post-event (wind, flood) resilience

6. Cost and Consequences

- Repair cost for Unit 14 is estimated at Approx. AUD $68,000

- Insurance declined coverage due to “non-compliant rectification methodology”

- Two caravans became structurally uninhabitable and required removal.

Additionally, residents experienced:

- Uneven flooring

- Jamming doors and windows

- Increased vibration and noise during occupation

7. Root Causes

- Lack of qualified personnel

- Improper lifting equipment and methods

- Failure to follow staged lifting procedures

- Inadequate support block construction

- No engineering oversight

8. Conclusion

This case study highlights the significant risks of non-compliant lifting of caravan homes on block foundations. The lightweight and flexible nature of caravans—combined with concentrated support points—makes them highly vulnerable to distortion when lifted incorrectly.

The damage observed in Caravan Unit 14 shows that:

- Even small lifting errors can result in major structural failures

- Repairs can exceed the value of the caravan

- Non-compliant work voids insurance and creates safety hazards

Adhering to proper lifting techniques and Australian Standards is essential to preserving structural integrity and ensuring occupant safety.